Applications

Perfect Energy

Reduce Energy Consumption, Increase Efficiency

Can Energy Usage Be Tamed?

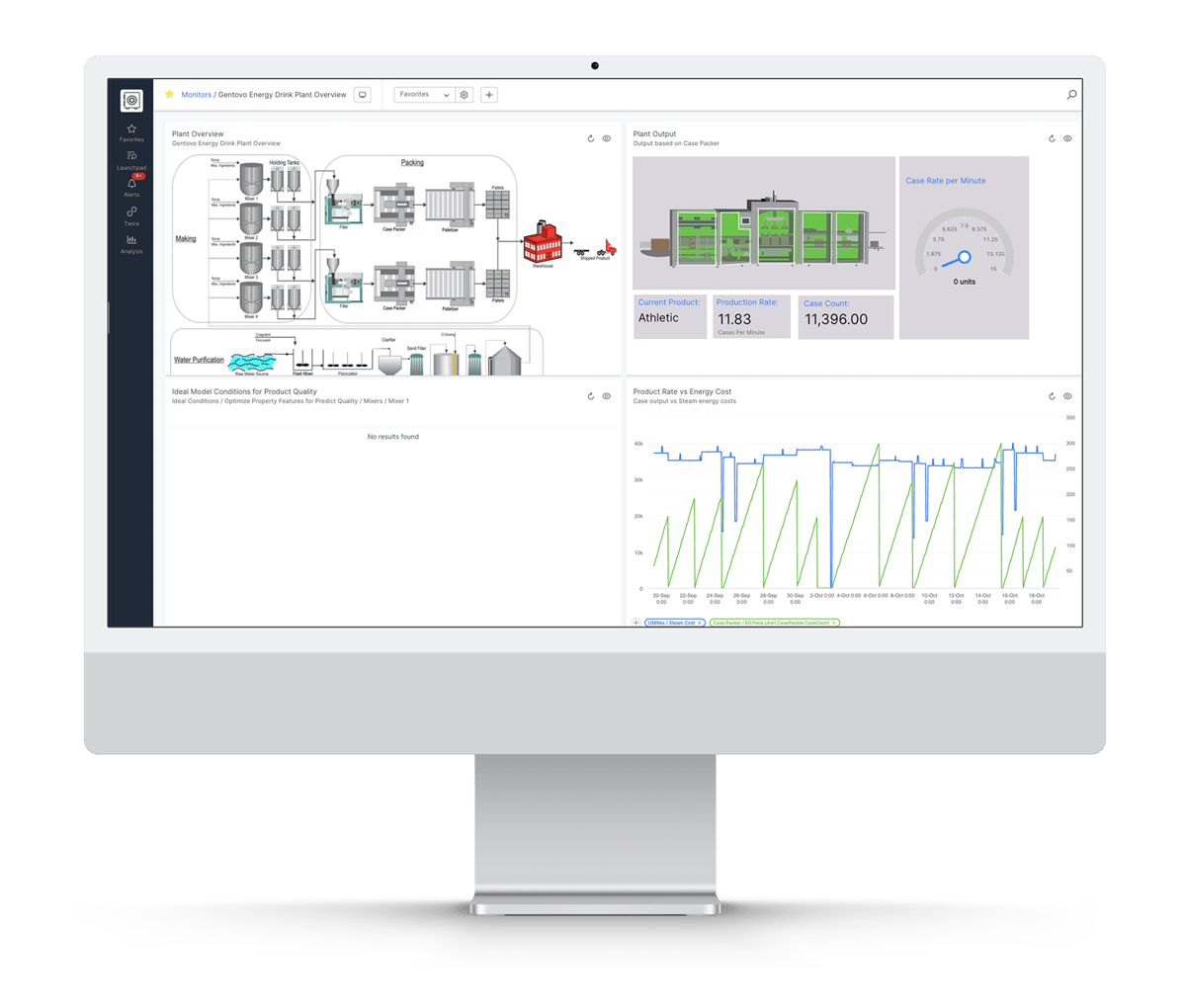

Short answer, yes. And not by shutting down your equipment either. The key is connecting energy consumption data in context to production and asset usage - identifying energy gluttons and what causes them, alerting you to shifts in real-time, and, if you want, automatically correcting them.

Accelerates Learning

- See by-line, by-product energy performance

- Identify the best recipes/centerlines to minimize energy

- Understand top drivers for high energy consumption

- Prioritize trial opportunities to reduce energy

Drives Insights to Action

- See real-time anomalies driving energy consumption higher than optimum

- Understand the energy impact of process changes and operating procedures

- Act on real-time recommendations to lower energy consumption