OEMs and Equipment Service Providers

A Platform For

Proactively optimizing the performance of your fleet of equipment has never been more important in today’s competitive environment.

With TwinThread, you can create a Virtual Operations Center that harnesses the power of Industrial AI and Digital Twins to increase productivity, reduce downtime, and improve energy efficiency of your equipment in your end-customer’s operations.

We serve a broad range of industries

and equipment types

TwinThread specializes in complex or highly scaled fleets where uptime, efficiency, and serviceability are paramount.

Medical

Devices

HVAC & Home Automation

Data

Centers

Mining & Construction Equipment

Mobile

Plants

Oil &

Gas

Skids & Modular Plants

We empower you to deliver results

Augment fleet performance by integrating Industrial AI today. Tackle common productivity challenges, enhance reliability, reduce the risk of failure, and enable your experts to make the right decisions rapidly at scale.

Monetize fleet reliability and performance

Greater reliability = greater profitability. Through Industrial AI and Digital Twins, you can unlock your fleet's full potential and create new opportunities for revenue generation.

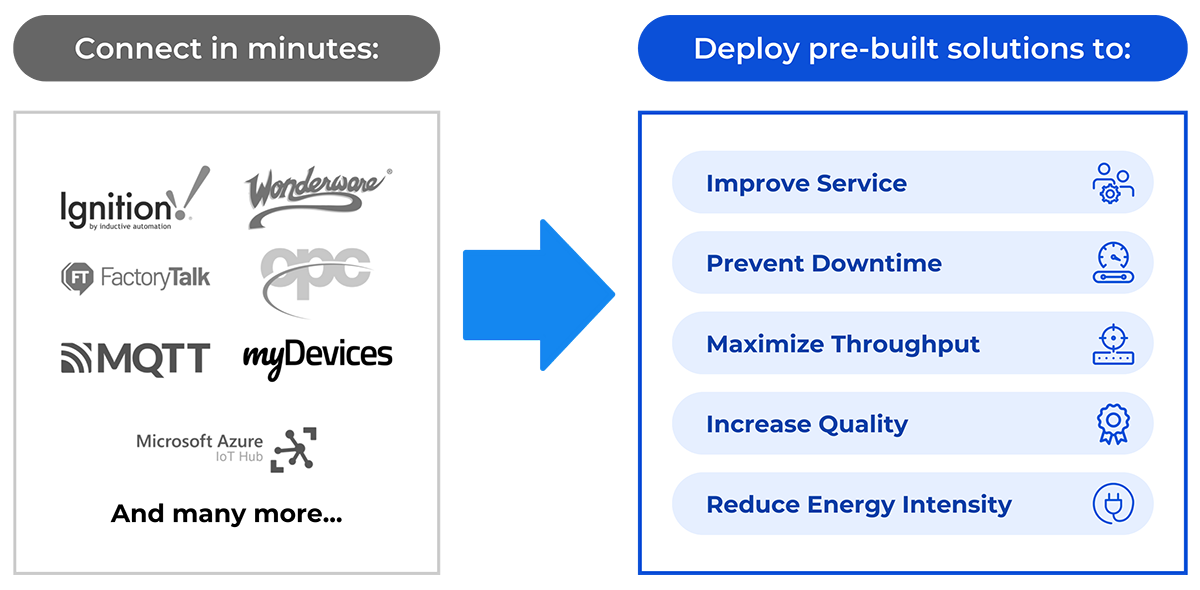

Connect with all types of sensors and equipment automation

TwinThread is agnostic and connects to the broadest array of data sources. Combine disparate asset data with Digital Twins and Industrial AI to create a complete picture of fleet health and get the most from your legacy data infrastructure and automation.

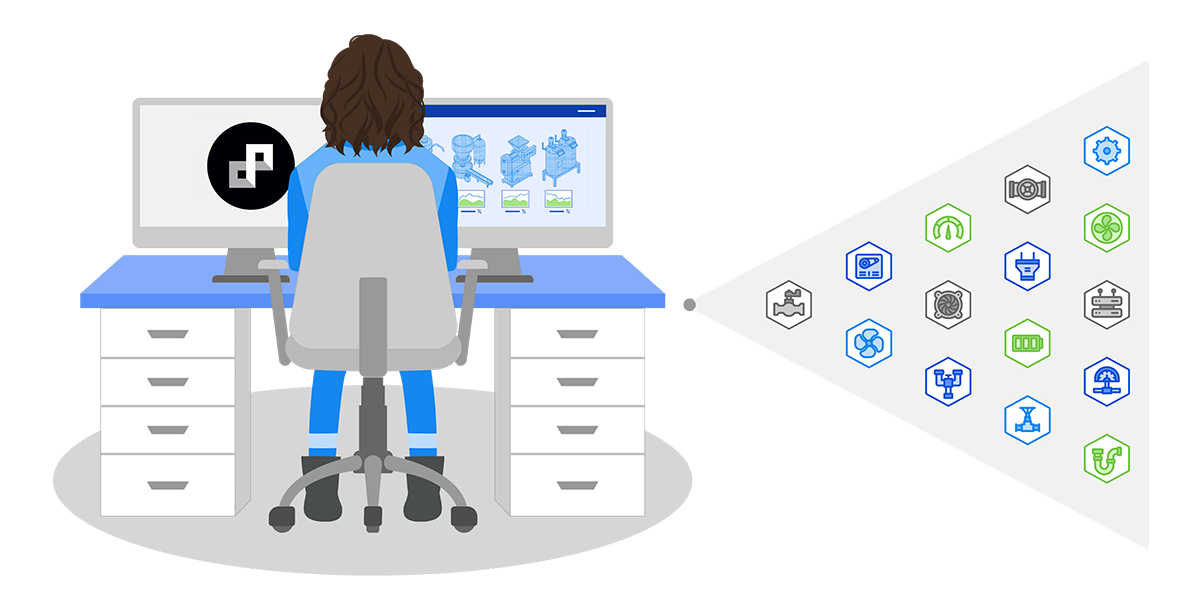

Create fleet-wide monitoring rules in minutes

Without help, establishing monitoring rules for your whole fleet is daunting. TwinThread's pre-built solutions automate these time-consuming tasks and identify opportunities for continuous optimization–freeing your experts to focus on work that delivers more value.

Make your smart equipment even smarter

New equipment is not a prerequisite for optimization. TwinThread’s Industrial AI and Digital Twins evolves the intelligence of your existing assets, going beyond current limitations and accelerating your Continuous Improvement process.

Create a Virtual Operations Center with ease

TwinThread gives you the tools to rapidly build and deploy a Virtual Operations Center. Monitor asset health and coordinate actions, improve performance, and fully operationalize Industrial AI fleet-wide.

Scale the impact of your unique expertise

Your experts know your systems best. With TwinThread, you can digitize management best practices and effectively multiply expertise across your fleet. Empower your experts to provide the greatest possible impact and drive maximum value.

We understand how to scale

Over 30 years of experience in industrial automation and a track record of delivering some of the most highly-scaled IoT and Analytics solutions in the world have taught us what it takes to fully realize the benefits of Industrial AI.

Real Solutions. Real Scale. Real Results.

Webinar

The Virtual Operations Center: Accelerating Industrial Transformation with Less People & More Intelligent Tech

Expand your innovators

Using TwinThread, you don’t need to be a software developer or data scientist to apply Industrial AI. Extend the reach of your equipment experts with no-code development tools that facilitate rapid innovation.

Flexible options for telemetry and automation

Whether you are retrofitting old devices or designing new ones, TwinThread offers an open and flexible approach to take full advantage of the sensors and automation capabilities you have today and plan to have tomorrow.

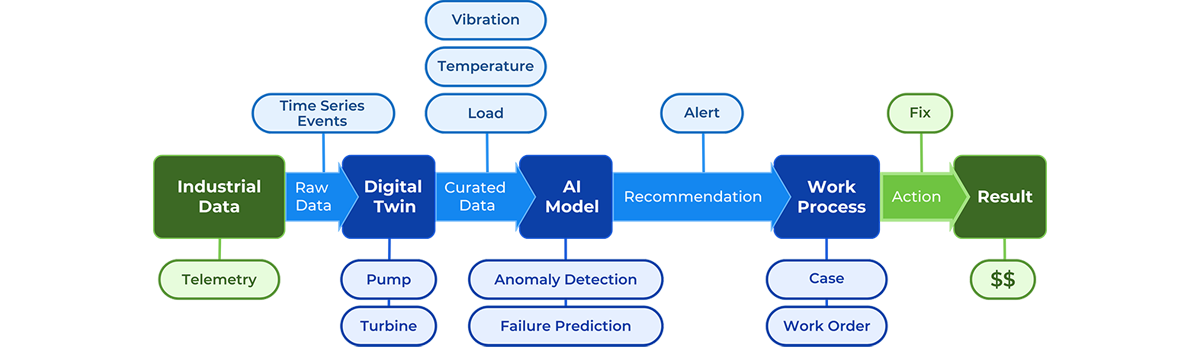

Go beyond fleet insights

Insights without action are worthless. TwinThread gives you everything you need to fully operationalize Industrial AI across your fleet of equipment. Move from data collection, to insights, to automated actions with ease.

What is “operationalization"?

The process of turning insights into action.

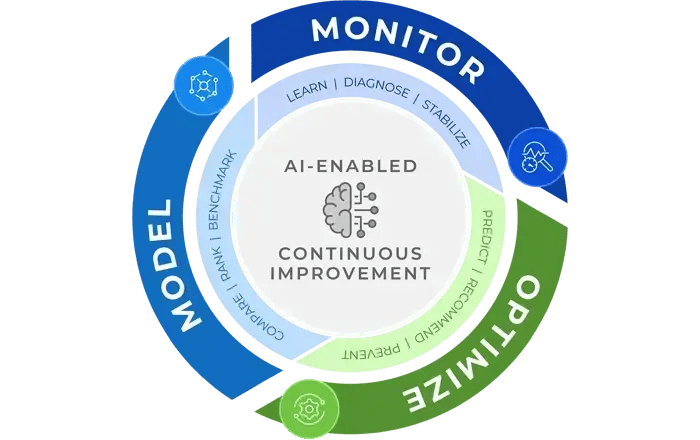

Bring modern continuous improvement to your customers

When your fleet is connected with TwinThread you can model, monitor, and optimize faster and with higher impact than ever before. Digital Twins provide the framework to standardize and scale, while Industrial AI provides the capabilities to work smarter and drive automation to new levels.

AI-Enabled Continuous Improvement

- Model:

- Compare

- Rank

- Benchmark

- Monitor:

- Learn

- Diagnose

- Stabilize

- Optimize:

- Predict

- Recommend

- Prevent

Create your Virtual Operations Center

Extend the reach of your experts to deploy and manage improvement initiatives across your entire fleet.

AI-Enabled Continuous Improvement

- Model:

- Compare

- Rank

- Benchmark

- Monitor:

- Learn

- Diagnose

- Stabilize

- Optimize:

- Predict

- Recommend

- Prevent

Ready to learn more about how TwinThread works?

Stay Connected with Industrial AI Trends and Platform Features

Get quarterly updates from our experts. Stay ahead with insights and strategies for digital transformation and operational excellence.